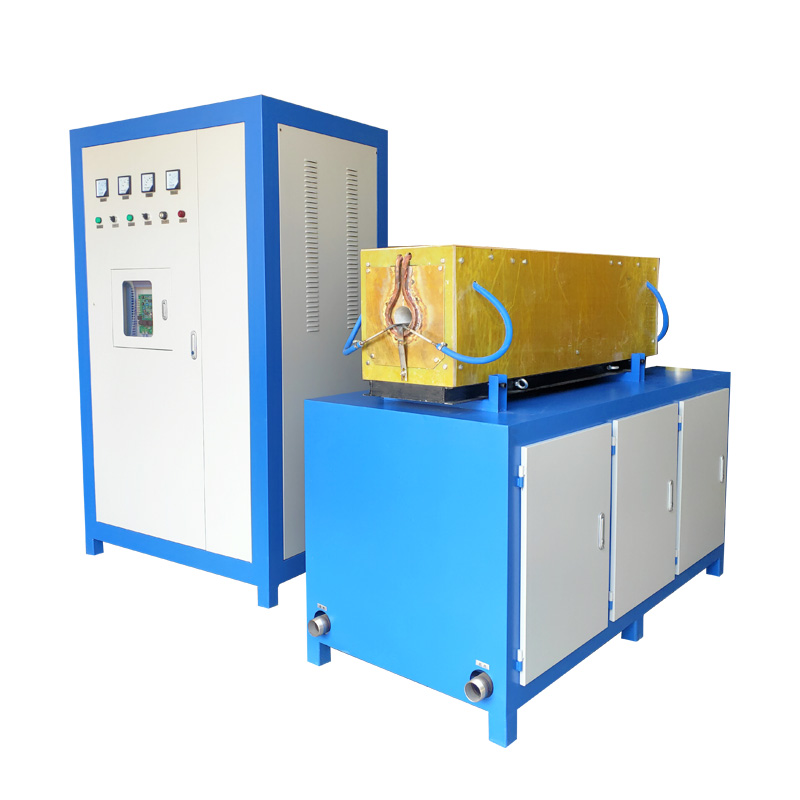

The composition of the thyristor intermediate frequency forging diathermy furnace:

The thyristor intermediate frequency forging diathermy furnace is composed of intermediate frequency power supply, inductor furnace body, furnace body platform, cylinder feeding device (automatic feeder) time control system, infrared temperature sorting mechanism and other parts; (optional automatic manipulator according to needs ).

The intermediate frequency power supply is to convert the three-phase power frequency alternating current into direct current through the rectifier circuit, and then output the single-phase intermediate frequency alternating current through the inverter circuit to supply the intermediate frequency coreless induction furnace, and then use the principle of electromagnetic induction to place the workpiece in the alternating magnetic field to generate eddy currents. And heating, to meet the heating requirements of smelting, quenching, diathermy, etc.

Features of thyristor intermediate frequency forging diathermy furnace:

1. Fast heating speed and less oxidative decarbonization

2. The degree of automation is high, which can realize automatic unmanned operation and improve labor productivity.

3. Uniform heating and high temperature control accuracy

4. The induction furnace body is easy to replace. According to the size of the workpiece, different specifications of the induction furnace body need to be configured. Each furnace body is designed with a water and electricity quick-change joint, which makes the furnace body replacement simple, fast and convenient.

5. The whole machine is equipped with water temperature, water pressure, phase loss, overvoltage, overcurrent, voltage limit/current limiter, start overcurrent, constant current and buffer start, so that the equipment starts smoothly, the protection is reliable and fast, and the operation is stable.

6. Low energy consumption, high efficiency of non-polluting heating, and the equipment meets the requirements of environmental protection.

SCR medium frequency forging diathermy furnace induction coil:

The induction coil of the round steel diathermy furnace should be fired with an oxygen-free red copper square thick-walled tube with a purity of 99.9%. In order to strengthen the insulation of the induction coil, the insulation strength of the inductor is applied to the rated voltage plus 2000V without breakdown and flickering. The surface coating is silicone enamel 167, and the insulation resistance is not less than 1M when the rated voltage is 2000V. The inner, outer walls and turns of the induction coil are coated with special charge for diathermy furnace (including more than a dozen materials such as diamond, capacitor magnesia, etc., with a refractoriness of 1800°C), which can greatly prolong the service life of the inductor and reduce the maintenance investment in the later period. . It has a high degree of insulating properties and thermal insulation properties to protect the induction coil from damage when the inner lining is damaged.

浙公網安備 33038102331513號

浙公網安備 33038102331513號